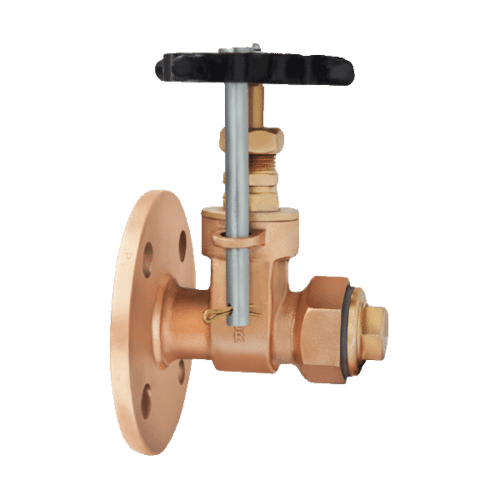

CI004 Cast Iron Gate Valve Class-125 (Flanged)

Price 1110 INR/ Number

CI004 Cast Iron Gate Valve Class-125 (Flanged) Specification

- Connection

- Flanged

- Size

- DN40 to DN300

- Sealing

- Rubber/Metal

- Structure

- Rising Stem

- Material

- Cast Iron

- Type

- Gate Valve

- Power Source

- Manual

- Pressure

- Class-125 (17.6 bar)

- Media

- Water, Oil, Gas

- Working Temperature

- -10C to 120C

- Port Size

- 1.5 inch to 12 inch

- Surface

- Epoxy Painted

- Shape

- Round

- Stem Material

- Stainless Steel

- Handwheel Material

- Cast Iron

- Application

- Industrial, Water Supply, Sewage

- Face to Face Dimension

- As per BS 5163

- Bonnet Type

- Bolted Bonnet

- Body Test Pressure

- 24 bar

- End Connection

- ANSI B16.1 Class 125 Flange

- Coating Thickness

- Minimum 250 microns

- Seat Test Pressure

- 18 bar

About CI004 Cast Iron Gate Valve Class-125 (Flanged)

- Item Code: CI0004

- Pressure Rating: CL-125

- Testing Standard: Mfg. Standard

- Size Range: 40mm to 300mm

- Product Standard: Mfg. Standard

Suitable For

Material Specification

| P. NO. | NAME OF PART | MATERIAL | SPECIFICATION |

|---|---|---|---|

| 1 | BODY | CAST IRON | BSEN 1561 Gr.ENGJL 200 |

| 2 | STEM NUT | CAST IRON | BSEN 1561 Gr.ENGJL 200 |

| 3 | WEDGE | CAST IRON | BSEN 1561 Gr.ENGJL 200 |

| 4 | GASKET | C.N.A.F | B.S. 1832 |

| 5 | BONNET | CAST IRON | BSEN 1561 Gr.ENGJL 200 |

| 6 | BOLTS & NUTS | CARBON STEEL | BS 4190 |

| 7 | T-HEAD BOLTS & NUTS | CARBON STEEL | BS 4190 |

| 8 | GASKET | C.N.A.F | B.S. 1832 |

| 9 | STUFFING BOX | CAST IRON | BSEN 1561 Gr.ENGJL 200 |

| 10 | PACKING | TO SUIT SERVICE CONDITIONS | |

| 11 | GLAND FLANGE | CAST IRON | IS 2062 Gr. A |

| 12 | STEM | CARBON STEEL | IS 2062 Gr. B |

| 13 | HAND WHEEL | CAST IRON | BSEN 1561 Gr.ENGJL 200 |

| 14 | WASHER | CARBON STEEL | ANY GRADE |

| 15 | BOLT FOR HAND WHEEL | CARBON STEEL | BS 4190 |

Robust Construction & Versatile Application

Constructed from premium cast iron and featuring a stainless steel stem, the CI004 Gate Valve ensures durability across various industrial settings. Designed for handling water, oil, or gas, it is highly suitable for water supply, sewage treatment, and industrial fluid management. The bolted bonnet and rising stem structure contribute to a long operational lifespan and low maintenance requirements.

Superior Sealing and Reliable Performance

With options for rubber or metal seat sealing, the valve provides dependable shutoff under all operating pressures, ensuring system integrity. The epoxy painted surface protects against corrosion and external damage, while the bolted bonnet design allows for safe and straightforward servicing. The valve withstands a test pressure of 24 bar for the body and 18 bar for the seating.

Compliant and Flexible Sizing

Complying with ANSI B16.1 Class 125 and BS 5163, the CI004 valve meets international standards for flanged end connections and face-to-face dimensions. Its broad port size range (1.5 inch to 12 inch) allows for wide-ranging installation in pipelines of varying diameters, making it a practical choice for distributors, suppliers, and wholesalers across India.

FAQ's of CI004 Cast Iron Gate Valve Class-125 (Flanged):

Q: How is the CI004 Cast Iron Gate Valve installed in a pipeline?

A: The CI004 Gate Valve features ANSI B16.1 Class 125 flanged ends, allowing straightforward bolted connection to compatible pipeline flanges. Standard installation procedures should be followed, ensuring proper alignment and gasket sealing before tightening the bolts.Q: What are the typical applications of this gate valve?

A: This gate valve is suited for industrial purposes, water supply, and sewage systems. Its robust construction and epoxy coating make it ideal for use with water, oil, or gas in municipal, industrial, or commercial piping networks.Q: When should a cast iron gate valve with a rising stem be selected?

A: A rising stem gate valve like the CI004 is recommended when clear stem position indication (open or closed) is necessary. It is also ideal for applications requiring reliable shutoff, easy maintenance, and visual verification of operational status.Q: Where can the CI004 Cast Iron Gate Valve be sourced in India?

A: This valve is available through authorized distributors, suppliers, and wholesalers across India. Companies specializing in industrial valves and pipeline components typically stock this model or can procure it on request.Q: What benefits does the epoxy-coated surface provide?

A: The minimum 250-micron epoxy coating delivers excellent resistance to corrosion and environmental wear, significantly extending the valve's lifespan, particularly in harsh or humid environments.Q: How is the sealing achieved in the CI004 valve?

A: The valve employs either rubber or metal seat sealing to ensure an effective shutoff. This design minimizes the risk of leakage and accommodates a range of media, including water, oil, and gas.Q: What is the process for maintenance or servicing of this gate valve?

A: The bolted bonnet design allows for hassle-free disassembly and maintenance. Periodic inspection of the sealing surfaces, stem, and bonnet is recommended to ensure continued optimal performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gate Valve Category

FCS022 Forged Steel Gate Valve Welded Bonnet Class-2500 (Socket Weld / Butt Weld)

Price 1085 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : 1/2 to 2 (DN15 to DN50)

Material : Other , Forged Carbon Steel ASTM A105

Type : Other, Forged Steel Gate Valve

Structure : Other, Welded Bonnet

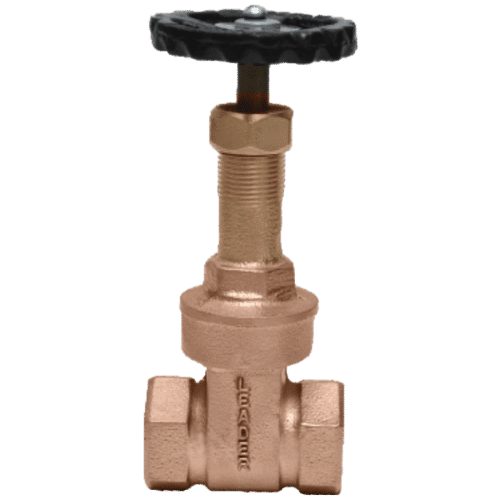

IS002 Gun Metal / Bronze Gate Valve Class-1 (Screwed)

Price 1115 INR / Number

Minimum Order Quantity : 100

Size : 15mm to 100mm

Material : Other , Gun Metal / Bronze

Type : Other, Gate Valve

Structure : Other, Rising Stem, Solid Wedge

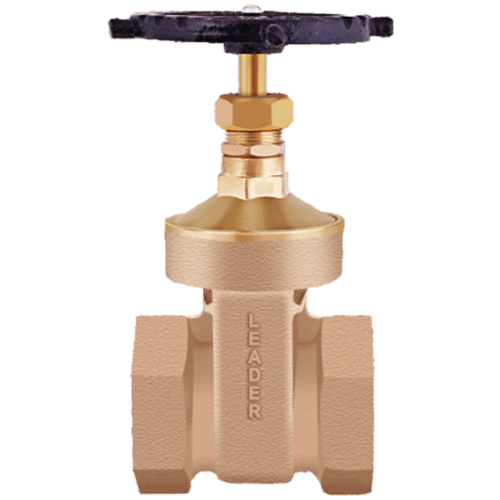

IS001 Gun Metal/ Bronze Gate Valve Class-1 (Screwed)

Price 1050 INR / Number

Minimum Order Quantity : 100

Size : Standard

Material : Other

GM192 Gun Metal/ Bronze Gate Valve PN-16 (Mixed Ends)

Price 1065 INR / Number

Minimum Order Quantity : 100

Size : Standard

Type : Gate Valve

Structure : Gate

CELESTE TRADING CORPORATION

GST : 27AADFC6410F1ZV

GST : 27AADFC6410F1ZV

6, Gulmohar Orchids, First Floor, Bibwewadi Kondhwa Rd, Sahaney Sujan Park, Lullanagar,Pune - 411040, Maharashtra, India

Phone :07317168914

|

|

CELESTE TRADING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry