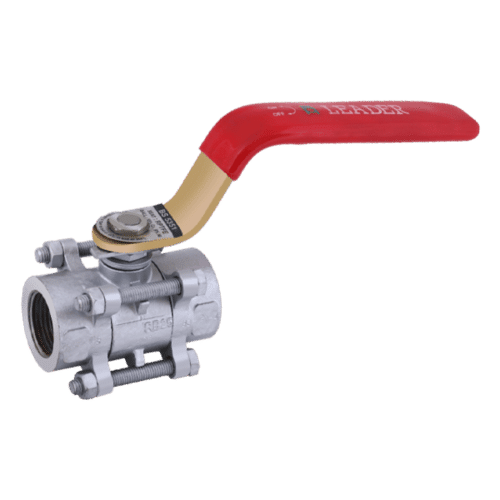

GM103 Gun Metal / Bronze Venturi Port Ball Valve Class-150 (Flanged)

Price 1080 INR/ Piece

MOQ : 100 Pieces

GM103 Gun Metal / Bronze Venturi Port Ball Valve Class-150 (Flanged) Specification

- Channels

- Two / Single Flow Channel

- Pressure

- Class 150 (Up to 285 psi at 38C)

- Structure

- Venturi Port Ball Valve

- Connection

- Flanged

- Caliber

- Full Bore / Reduced Port

- Material

- Gun Metal / Bronze

- Power

- Manual

- Media

- Water, Oil, Gas, Chemicals

- Temperature of Media

- Up to 150C

- Port Size

- 15mm to 150mm

- Flange

- ANSI B 16.5 Class 150

- Finish

- Smooth / Machined

- Application

- General Industrial, Water Treatment, Chemical Processing, Oil & Gas

- Valve Type

- 2-Piece Construction

- Leakage Class

- Class VI (Zero Leakage)

- Face To Face Dimension

- As Per ASME B16.10

- Handle Type

- Lever Operated

- Testing Standard

- API 598

- Stem Material

- Stainless Steel

- Packing Material

- PTFE

- Corrosion Resistance

- Superior against saline water

- Suitable Flow

- Venturi Effect For Metering/Reduced Pressure Drop

- Body Material

- IS 318 Gr.LTB2 (Bronze)

- Seat Material

- PTFE

- Design Standard

- BS EN ISO 17292

- Ball Material

- Brass / Stainless Steel

- Working Pressure

- Up to 150 lbs

- Operation

- Quarter Turn

- End Connection Standard

- Flanged Ends as per ANSI B16.5

GM103 Gun Metal / Bronze Venturi Port Ball Valve Class-150 (Flanged) Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 7 Days

About GM103 Gun Metal / Bronze Venturi Port Ball Valve Class-150 (Flanged)

- Item Code: GM103

- Pressure Rating: CL-150

- Testing Standard: BSEN 12266 PART-1

- Size Range: 15mm to 100mm

- Product Standard: Mfg. Standard

-

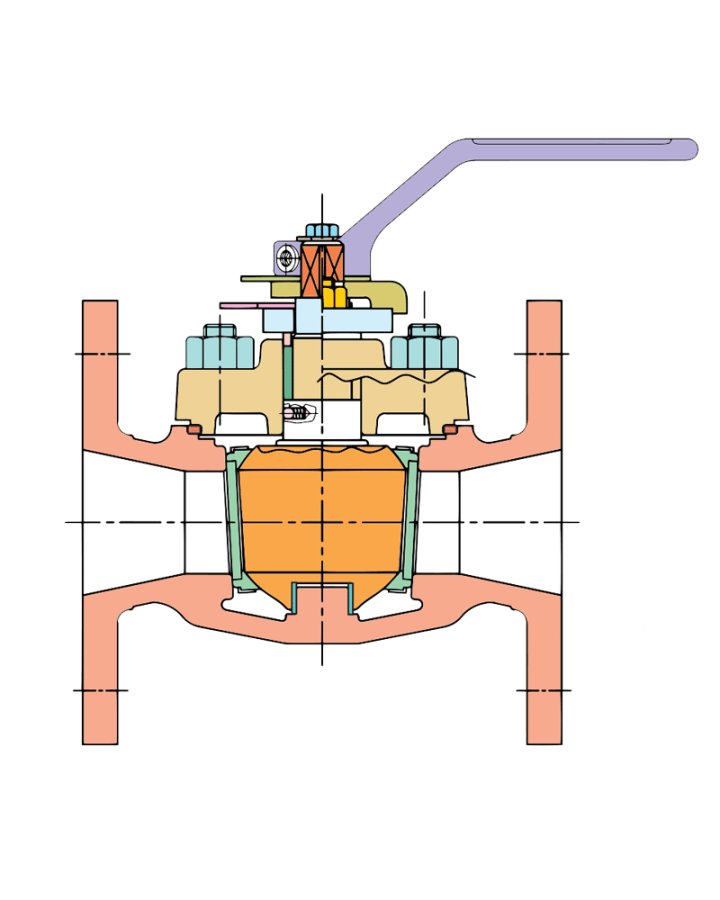

Material Specification

P. No. NAME OF PART MATERIAL SPECIFICATION 1 BOLT AL. BRONZE NES 862 2 WASHER GUN METAL BSEN 1982 Gr.CC491K 3 HANDLE C.C.S. / C.S.S. (WITH PVC GRIP) / S.S. ASTM A216 Gr. WCB/ ASTM A351 CF8M/ BS 970 SS 316 (FABRICATED) 4 UPPER LOCK PLATE BRASS SHEET IS 410 5 STOPPER BRASS SHEET IS 410 6 LOWER LOCKING PLATE BRASS SHEET IS 410 7 GLAND FLANGE GUN METAL BSEN 1982 Gr.CC491 K 8 GLAND FOLLOWER PH. BRONZE BS 2874 PB 102 9 GLAND PACKING PTFE 10 ANTISTATIC DEVICE STAINLESS STEEL AISI 304 11 BONNET GUN METAL BSEN 1982 Gr. CC491K 12 GASKET VITON B 13 SEAT PTFE REINFORCED WITH 90 / 10 CU,NI 14 BALL GUN METAL BSEN 1982 Gr.CC491 K 15 BODY GUN METAL BSEN 1982 Gr.CC491 K 16 BUSHING REINFORCED PTFE. 17 STUDS & NUTS H.T. BRASS DIN EN 12165 GR. CW721 R 18 GLAND STUDS & NUTS H.T. BRASS DIN EN 12165 GR. CW721 R

Superior Corrosion Resistance for Harsh Environments

Thanks to its gun metal/bronze construction and stainless steel internals, the GM103 valve offers superior resistance to corrosionespecially from saline water. This makes it ideal for coastal, marine, and water treatment applications where long-term reliability in challenging conditions is essential.

Precision Flow Control and Metering with Venturi Port Design

The venturi port structure provides accurate flow metering and ensures reduced pressure drop, enhancing overall process efficiency. This feature is particularly valuable in industrial applications requiring precise flow control, such as chemical processing and oil & gas metering.

Zero Leakage and Reliable Operation

Designed and tested to API 598 standards, the GM103 achieves Class VI (zero leakage) performance. The quarter-turn lever operation ensures quick, dependable valve actuation, while PTFE packing and seats extend service life and reduce maintenance needs.

FAQs of GM103 Gun Metal / Bronze Venturi Port Ball Valve Class-150 (Flanged):

Q: How does the venturi port design of the GM103 ball valve benefit industrial applications?

A: The venturi port design minimizes pressure drop and enables precise metering of flow, making it ideal for processes requiring controlled and efficient fluid movement such as in chemical, water treatment, and oil & gas applications.Q: What materials are used in the construction of the GM103 valve, and how do they enhance its durability?

A: The GM103 features a gun metal or bronze body (IS 318 Gr.LTB2), brass or stainless steel ball, stainless steel stem, and PTFE components. These materials offer excellent corrosion resistance and durability, especially in saline or chemically aggressive environments.Q: When is it appropriate to use this valve in a system?

A: This valve is suitable whenever precise flow control and reliable shutoff are needed in systems handling water, oil, gas, or chemicals, especially where Class VI (zero leakage) and resistance to saline water are required.Q: Where can the GM103 ball valve be installed?

A: It can be installed in a range of settings, including water treatment plants, industrial processing facilities, chemical plants, and oil & gas infrastructure. The flange ends (ANSI B16.5) accommodate standard piping connections for these industries.Q: What is the process for operating the GM103 ball valve?

A: Operation is manual and lever-operated, requiring a simple quarter-turn to open or close the valve fully. This design allows rapid response and straightforward control for operational safety and convenience.Q: How does the valves leakage class ensure system safety?

A: The valve is built and tested to achieve Class VI (zero leakage) according to API 598, ensuring no fluid passes through when closed, which is crucial for safety, process integrity, and environmental protection.Q: What are the temperature and pressure limits for media in the GM103 valve?

A: The GM103 is rated for media temperatures up to 150C and operating pressures up to 150 lbs (approximately 285 psi at 38C), covering a wide range of industrial requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ball Valve Category

IVTLE Intervalve

Price 1080 INR / Number

Minimum Order Quantity : 100

Color : Silver

Size : Different Sizes Available

Material : Cast Iron

CSS013 Cast Stainless Steel Ball Valve 3- Piece Full Bore (Screwed)

Price 1025 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Silver

Size : Different Sizes Available

Usage : Water Supply

Material : Cast Iron

CSS012 Cast Stainless Steel Ball Valve 3- Piece (Screwed)

Price 1020 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Silver

Size : Different Sizes Available

Usage : Water Supply

Material : Stainless Steel

WCB013 Cast Steel Ball Valve 3- Piece Full Bore (Screwed)

Price 1050 INR / Number

Minimum Order Quantity : 100

Color : Silver

Size : Different Sizes Available

Usage : Water Supply

CELESTE TRADING CORPORATION

GST : 27AADFC6410F1ZV

GST : 27AADFC6410F1ZV

6, Gulmohar Orchids, First Floor, Bibwewadi Kondhwa Rd, Sahaney Sujan Park, Lullanagar,Pune - 411040, Maharashtra, India

Phone :07317168914

|

|

CELESTE TRADING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry