CI093 Cast Iron Y-Type Strainer PN-16 (Flanged)

Price 1130 INR/ Number

CI093 Cast Iron Y-Type Strainer PN-16 (Flanged) Specification

- Tensile Strength

- Min. 260 MPa

- Diameter

- Nominal Bore sizes 50 mm 300 mm

- Flexibility

- Rigid

- Thread Type

- Not Applicable (Flanged)

- Coating Type

- Fusion Bonded Epoxy

- Connection Type

- Flanged Ends (Drilled as per DIN/IS Standard)

- Sealing Type

- Gasketed Flanged Joint

- Temperature Range

- Up to 220C

- Tolerance

- 1 mm

- Yield Strength

- 170 MPa (min) typical

- Product Type

- Y-Type Strainer

- Material

- Cast Iron

- Connection

- Flanged

- Shape

- Y-Type

- Standard

- PN-16

- Surface Treatment

- Epoxy Painted

- Outer Diameter

- As per flange size (varies with NB size)

- Section Shape

- Cylindrical/Angular Body

- Length

- As per NB size and standard (refer to dimensional chart)

- Thickness

- As per IS 210/ISO 7268

- Color

- Blue

- Usage

- Industrial Liquid & Gas Filtration

- Rated Pressure

- PN-16 (16 bar)

- Application

- Water, Oil, Gas, Steam line filtration

- Material Grade

- IS 210 Gr. FG 260

- Face to Face Length

- Conforms to IS/BS standards

- Flow Direction

- Marked with Arrow on Body

- Drain Plug

- Provided (for screen cleaning)

- Hydrostatic Seat Test

- 17.6 bar

- Corrosion Resistance

- High due to Epoxy Coating

- Bolting Material

- Mild Steel (Galvanized) or Stainless Steel

- End Connection Standard

- Flanges Drilled as per IS 1538/BS 4504/DIN 2533

- Screen Material

- Stainless Steel (SS304/SS316)

- Screen Type

- Perforated or Mesh

- Installation Position

- Horizontal or Vertical

- Body Test Pressure

- 24 bar (Hydrostatic)

CI093 Cast Iron Y-Type Strainer PN-16 (Flanged) Trade Information

- Minimum Order Quantity

- 100 Number

- Supply Ability

- 1000 Per Week

- Delivery Time

- 7 Days

About CI093 Cast Iron Y-Type Strainer PN-16 (Flanged)

- Item Code: CI0093

- Pressure Rating: PN-16

- Testing Standard: Mfg. Standard

- Size Range: 40mm to 300mm

- Product Standard: Mfg. Standard

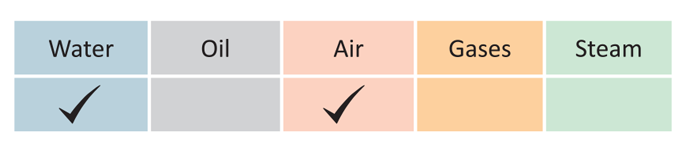

Suitable For

Material Specification

| P. NO. | NAME OF PART | MATERIAL | SPECIFICATION |

|---|---|---|---|

| 1 | BODY | CAST IRON | BSEN 1561 Gr. 200 |

| 2 | SCREEN | STAINLESS STEEL | TYPE 304 |

| 3 | GASKET | C.N.A.F. | IS 2712 Gr. C |

| 4 | COVER | CAST IRON | BSEN 1561 Gr. 200 |

| 5 | BOLTS | CARBON STEEL | BS 4190 |

| 6 | GASKET | C.N.A.F. | ------- |

| 7 | DRAIN PLUG | CAST IRON | BSEN 1561 Gr. GJL 200 |

Durability and Superior Filtration Performance

With a cast iron body graded IS 210 FG 260 and stainless steel screen material, the CI093 Y-Type Strainer guarantees robust construction and longevity. Its epoxy-coated surface ensures high corrosion resistance, while perforated or mesh screens optimize filtration. The strainer complies with international standards for pressure, dimensions, and connections, ensuring safe and efficient operation in demanding industrial environments.

Versatile Installation and Maintenance

The CI093 Y-Type Strainer is engineered for flexible installation, fitting both horizontal and vertical pipelines. Clearly marked flow direction and the provision of a drain plug simplify routine screening maintenance and cleaning. Its flanged ends meet major standards, making integration with existing systems straightforward and reliable.

FAQ's of CI093 Cast Iron Y-Type Strainer PN-16 (Flanged):

Q: How is the CI093 Cast Iron Y-Type Strainer installed in pipelines?

A: The CI093 Y-Type Strainer can be installed in either horizontal or vertical positions, making it suitable for versatile pipeline arrangements. Flow direction is indicated by an arrow marked on the body, ensuring correct alignment during installation. The flanged ends, drilled as per IS 1538, BS 4504, or DIN 2533 standards, allow for easy connection to compatible piping systems.Q: What types of fluids can the CI093 Y-Type Strainer filter?

A: This strainer is suitable for filtration of various industrial fluids including water, oil, gas, and steam. Its robust construction and gasketed flanged joint enable reliable operation in liquid and gas filtration processes within a pressure range up to 16 bar and temperatures up to 220C.Q: When should the screen inside the strainer be cleaned?

A: The cleaning interval for the screen depends on the type and quantity of contaminants in the fluid being filtered. The CI093 is equipped with a drain plug, allowing for easy removal of accumulated debris and periodic maintenance. Regular inspection and cleaning help maintain optimal strainer performance and prevent pressure drop across the pipeline.Q: Where does the CI093 Y-Type Strainer typically find application?

A: This strainer is widely used in industrial settings such as water treatment plants, oil and gas transmission, and steam lines. Its durable design and high-pressure rating make it suitable for process lines requiring reliable filtration and corrosion resistance, supporting safe and efficient operation in diverse industrial environments across India.Q: What are the benefits of having high corrosion resistance in the CI093 Y-Type Strainer?

A: High corrosion resistance, achieved through fusion-bonded epoxy coating and stainless steel screens, ensures the strainer withstands harsh industrial conditions and extends service life. This minimizes maintenance frequency, prevents contamination, and enhances safety, making it a dependable option for long-term filtration requirements.Q: How does the strainer's face-to-face length conform to international standards?

A: The face-to-face length of the CI093 Y-Type Strainer adheres to IS and BS standards, ensuring dimensional compatibility with standard pipeline infrastructure. This facilitates straightforward integration and replacement within existing systems, reducing installation complexity and downtime.Q: What process is followed for hydrostatic testing of the CI093 strainer?

A: Each CI093 Y-Type Strainer undergoes stringent hydrostatic testing, with the body tested at 24 bar and the seat at 17.6 bar, verifying its ability to withstand operational pressure without leaks. This ensures reliability and safety before the strainer enters service in industrial filtration applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cast Iron Strainer Category

GM230 Gun Metal/ Bronze Y-Type Strainer PN-16 (Screwed)

Price 1085 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : Different Sizes Available

Material : Cast Iron

Usage : Water Supply

Color : Golden

CI092 Cast Iron Y-Type Strainer PN-16 (Screwed)

Price 1090 INR / Number

Minimum Order Quantity : 100

Size : Different Sizes Available

Material : Cast Iron

Usage : Water Supply

Color : Blue

DI076 Ductile Iron Y-Type Strainer PN-20 (Flanged)

Price 1120 INR / Number

Minimum Order Quantity : 100

Size : Different Sizes Available

Material : Cast Iron

Usage : Water Supply

Color : Blue

DI077 Ductile Iron Y-Type Strainer PN-25 (Flanged)

Price 1095 INR / Piece

Minimum Order Quantity : 100 Pieces

Size : Different Sizes Available

Material : Cast Iron

Usage : Water Supply

Color : Blue

CELESTE TRADING CORPORATION

GST : 27AADFC6410F1ZV

GST : 27AADFC6410F1ZV

6, Gulmohar Orchids, First Floor, Bibwewadi Kondhwa Rd, Sahaney Sujan Park, Lullanagar,Pune - 411040, Maharashtra, India

Phone :07317168914

|

|

CELESTE TRADING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry