CI061B Cast Iron Butterfly Valve PN-16 SS316 Disc (Wafer Type)

Price 1080 INR/ Number

CI061B Cast Iron Butterfly Valve PN-16 SS316 Disc (Wafer Type) Specification

- Connection

- Wafer Connection (Lugged as per request)

- Valve Type

- Butterfly Valve

- Material

- Body: Cast Iron, Disc: SS316, Shaft: Stainless Steel

- Power Source

- Manual

- Pressure

- PN-16

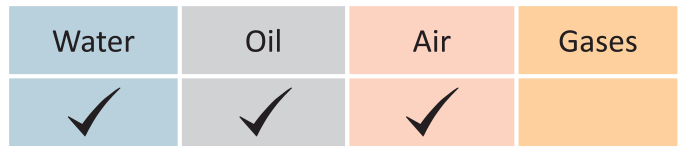

- Media

- Water, Oil, Gas, Air, Steam

- Working Temperature

- -10C to +120C

- Port Size

- 50 mm to 600 mm (2 to 24)

- Shape

- Wafer Type

- Leakage Rate

- Zero Leakage (Bubble Tight)

- Design Standard

- EN 593 / IS 13095

- Applications

- Water Treatment, HVAC, Fire Fighting, Process Industries

- Testing Standard

- BS EN 12266-1 / IS 13095

- Mounting

- Top Flange ISO 5211 for Actuator Mounting

- Seat Material

- EPDM / NBR

- Face to Face

- EN 558 Series 20 / ISO 5752

- Body Coating

- Fusion Bonded Epoxy Coated

- Shaft Material

- Stainless Steel AISI 410 / 431

- Operation

- Lever Operated (Gearbox Optional)

- End Connection

- Wafer to suit PN 10/16, ANSI 150 Flanges

- Disc Material

- Stainless Steel 316 (CF8M)

About CI061B Cast Iron Butterfly Valve PN-16 SS316 Disc (Wafer Type)

- Item Code: CI0061B

- Disc: SS(CF8M)

- Pressure Rating: PN-16

- Testing Standard: BSEN 12266 Part-1

- Size Range: 40mm to 350mm

- Product Standard: API 609 CAT. A.

Suitable For

Material Specification

| P. NO. | NAME OF PART | MATERIAL | ||

|---|---|---|---|---|

| 1 | GRUB SCREW | MILD STEEL | ||

| 2 | HANDLE | UP TO 6" | M.S. SHEET (IS 2062) FABRICATED (POWDER COATED) / C.C.S. (ASTM A216 Gr. WCB) | |

| 8" TO 12" | ||||

| 3 | L-KEY BOLT | CARBON STEEL | ||

| 4 | INDEXING PLATE | MILD STEEL (IS 2062) | ||

| 5 | NUT | CARBON STEEL | ||

| 6 | BODY | C.I. (EN 1561 Gr. GJL 200) | ||

| 7 | UPPER STEM | S.S. (ASTM A276 TYPE 410) OR ITS EQ. | ||

| 8 | MOULDED LINER | BUNA-N / EPDM (SHORE HARDNESS 70±4) | ||

| 9 | TAPER PIN | HANDENED STEEL | ||

| 10 | DISC | S.S. (ASTM A351 Gr.CF8M) | ||

| 11 | 'O' RING | BUNA-N / EPDM (SHORE HARDNESS 60±4) | ||

| 12 | BUSHING | PTFE | ||

| 13 | LOWER STEM | S.S. (ASTM A276 TYPE 410) OR ITS EQ. | ||

| 14 | GRUB SCREW | MILD STEEL | ||

| 15 | PACKING | BUNA-N / EPDM (SHORE HARDNESS 60±4) | ||

| 16 | GEAR BOX | ------ | ||

| 17 | HAND WHEEL | MILD STEEL (IS 2062) | ||

Engineered for Diverse Industrial Applications

The CI061B Cast Iron Butterfly Valve is ideal for sectors such as water treatment, HVAC, fire fighting systems, and various process industries. Engineered to ensure dependable isolation and flow control of media like water, oil, gas, air, and steam, it features a versatile wafer type design for easy installation and integration with different pipeline standards.

Reliable Performance with Premium Materials

Built with a cast iron body, stainless steel 316 disc, and shaft materials conforming to AISI 410/431, this valve guarantees long-lasting performance and resistance to corrosion. The fusion bonded epoxy coating prolongs the valve's service life, making it suitable for challenging environments and continuous operation.

Assured Safety and Bubble-Tight Sealing

The CI061B valve provides zero leakage (bubble tight) sealing thanks to the high-quality EPDM/NBR seat material and precision engineering, verified by testing standards such as BS EN 12266-1. This ensures safety and reliability in critical systems, while allowing easy inspection, maintenance, and actuator mounting via ISO 5211 top flange.

FAQ's of CI061B Cast Iron Butterfly Valve PN-16 SS316 Disc (Wafer Type):

Q: How is the CI061B Butterfly Valve installed in a piping system?

A: The CI061B butterfly valve is designed with a wafer connection, allowing it to be sandwiched between PN 10/16 or ANSI 150 flanges. Ensure alignment between the valve and flanges before tightening bolts evenly to achieve proper sealing. For specialized cases, a lugged configuration is available upon request.Q: What are the main benefits of the stainless steel 316 (CF8M) disc and shaft?

A: The use of stainless steel 316 (CF8M) for the disc and stainless steel (AISI 410/431) for the shaft provides excellent resistance to corrosion and wear, ensuring longer service life, especially in aggressive or damp environments like water treatment facilities and process industries.Q: When should the valve's gearbox operation be chosen over lever operation?

A: Gearbox operation is recommended for larger port sizes (typically above 300 mm) or when frequent fine throttling is required. It allows for smoother, more controlled actuation and reduces operating effort in high-pressure or large-diameter applications.Q: Where is this valve most effectively used?

A: The CI061B butterfly valve is optimized for water treatment plants, HVAC networks, fire protection systems, and a variety of process industries where reliable flow control and shut-off are vital. It can handle fluids such as water, oil, gas, air, and steam across a wide temperature range.Q: What standards does this valve comply with for design, face-to-face dimensions, and testing?

A: The valve is designed in accordance with EN 593 and IS 13095, features face-to-face dimensions as per EN 558 Series 20/ISO 5752, and testing follows BS EN 12266-1 or IS 13095 standards, ensuring international compatibility and consistent quality.Q: How is zero leakage (bubble-tight) achieved in this butterfly valve?

A: Zero leakage is attained through the use of precisely engineered EPDM or NBR seat materials and robust sealing mechanisms. Each valve undergoes rigorous testing per BS EN 12266-1 to ensure bubble-tight performance under rated pressure conditions.Q: What is the process for actuator mounting on this valve?

A: The valve incorporates a top flange designed to ISO 5211, making it straightforward to mount pneumatic or electric actuators. This feature enables seamless automation and integration into process control systems when manual operation is not sufficient.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Butterfly Valve Category

CI028 Cast Iron Butterfly Valve PN-16 SS304 Disc (Wafer Type)

Price 1105 INR / Number

Minimum Order Quantity : 100

Media : Water

Material : Cast Iron

Shape : Round

Pressure : Medium Pressure PSI

IVGTC Valve

Price 1075 INR / Number

Minimum Order Quantity : 100

Media : Water

Material : Cast Iron

Shape : Round

Pressure : Medium Pressure

IVDXR Valve

Price 1120 INR / Piece

Minimum Order Quantity : 100 Pieces

Media : Other, Air, Water, Gas, Oil

Material : Stainless Steel

Shape : Straight

Pressure : Other, Up to 10 Bar

IVGK 25 Butterfly Valve

Price 1120 INR / Piece

Minimum Order Quantity : 100 Pieces

Media : Water

Material : Cast Iron

Shape : Round

Pressure : Medium Pressure

CELESTE TRADING CORPORATION

GST : 27AADFC6410F1ZV

GST : 27AADFC6410F1ZV

6, Gulmohar Orchids, First Floor, Bibwewadi Kondhwa Rd, Sahaney Sujan Park, Lullanagar,Pune - 411040, Maharashtra, India

Phone :07317168914

|

|

CELESTE TRADING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry