CI061 Cast Iron Butterfly Valve PN-16 (Wafer Type)

Price 1060 INR/ Number

CI061 Cast Iron Butterfly Valve PN-16 (Wafer Type) Specification

- Connection

- Wafer/ Flange Compatible

- Valve Type

- Butterfly Valve (Wafer Type)

- Material

- Cast Iron

- Power Source

- Manual

- Pressure

- PN-16

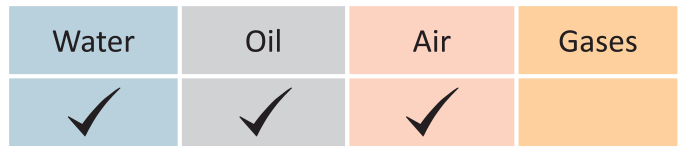

- Media

- Water, Air, Oil, Gas, Steam

- Working Temperature

- -10C to +80C

- Port Size

- 2 inch to 24 inch

- Shape

- Wafer

- End Connection

- Compatible with PN10/PN16/ANSI 150 Flange Standards

- Face to Face Standard

- ISO 5752

- Application

- Water Treatment, HVAC, Fire Protection, Industrial Pipelines

- Leakage Class

- Class VI

- Seat Material

- EPDM/ NBR/ PTFE

- Operation

- Lever/ Gear Operated

- Disc Material

- Ductile Iron/ Stainless Steel

- Body Coating

- Fusion Bonded Epoxy Coated

- Design Standard

- IS:13095

- Stem Material

- Stainless Steel

About CI061 Cast Iron Butterfly Valve PN-16 (Wafer Type)

- Item Code: CI0061

- Disc: Ductile IRON

- Pressure Rating: PN-16

- Testing Standard: BSEN 12266 Part-1

- Size Range: 40mm to 350mm

- Product Standard: BS 5155

Suitable For

Material Specification

| P. NO. | NAME OF PART | MATERIAL | ||

|---|---|---|---|---|

| 1 | GRUB SCREW | MILD STEEL | ||

| 2 | HANDLE | UP TO 6" | M.S. SHEET (IS 2062) FABRICATED (POWDER COATED) / C.C.S. (ASTM A216 Gr. WCB) | |

| 8" TO 12" | ||||

| 3 | L-KEY BOLT | CARBON STEEL | ||

| 4 | INDEXING PLATE | MILD STEEL (IS 2062) | ||

| 5 | NUT | CARBON STEEL | ||

| 6 | BODY | C.I. (EN 1561 Gr. GJL 200) | ||

| 7 | UPPER STEM | S.S. (ASTM A276 TYPE 410) OR ITS EQ. | ||

| 8 | MOULDED LINER | BUNA-N / EPDM (SHORE HARDNESS 70±4) | ||

| 9 | TAPER PIN | HANDENED STEEL | ||

| 10 | DISC | D.I. (ASTM A395) | ||

| 11 | 'O' RING | BUNA-N / EPDM (SHORE HARDNESS 60±4) | ||

| 12 | BUSHING | PTFE | ||

| 13 | LOWER STEM | S.S. (ASTM A276 TYPE 410) OR ITS EQ. | ||

| 14 | GRUB SCREW | MILD STEEL | ||

| 15 | PACKING | BUNA-N / EPDM (SHORE HARDNESS 60±4) | ||

| 16 | GEAR BOX | ------ | ||

| 17 | HAND WHEEL | MILD STEEL (IS 2062) | ||

Reliable Performance Across Industries

Engineered to meet IS:13095 standards and featuring compatibility with a range of flanges, the CI061 Cast Iron Butterfly Valve offers outstanding reliability for water treatment, HVAC systems, fire protection, and industrial pipelines. The robust construction paired with fusion bonded epoxy coating ensures a long service life even in demanding environments.

Flexible Operation and Wide Compatibility

Available with lever or gear operation, the valve provides ease of use and accurate flow regulation. With wafer type face-to-face dimensions compliant with ISO 5752 and the capacity to connect to PN10, PN16, and ANSI 150 flanges, installation is straightforward and adaptable to new or existing setups.

FAQ's of CI061 Cast Iron Butterfly Valve PN-16 (Wafer Type):

Q: How is the CI061 Cast Iron Butterfly Valve typically installed?

A: This wafer type valve is installed between two flanges and is compatible with PN10, PN16, or ANSI 150 flange standards. Its flexible design allows for easy integration into new or existing pipelines without the need for extensive modifications.Q: What media can the CI061 Butterfly Valve handle?

A: The valve can control the flow of water, air, oil, gas, and steam, making it suitable for a broad range of applications within water treatment plants, HVAC systems, fire protection networks, and other industrial processes.Q: When should I use a lever-operated version vs. a gear-operated version?

A: Lever operation is ideal for smaller valve sizes or when quick open/close action is needed. Gear operation is preferred for larger sizes (usually above 8 inches), or when precise flow modulation and reduced manual effort are important.Q: Where can this butterfly valve be utilized in industrial systems?

A: The CI061 valve is suitable for use in water distribution, cooling and heating circuits (HVAC), fire protection systems, and process pipelines in various industrial settings where manual flow control is required.Q: What is the process for selecting the appropriate seat and disc material?

A: Selection depends on the application's media and temperature range. EPDM is suitable for most water applications, NBR offers compatibility with oil and gas, and PTFE provides chemical resistance. Disc options-ductile iron or stainless steel-are chosen based on the corrosiveness or abrasiveness of the media.Q: What are the main benefits of using the CI061 Wafer Type Butterfly Valve?

A: Key benefits include its durable construction, corrosion-resistant epoxy coating, versatile seat and disc material options, ease of operation, leakage tightness (Class VI), straightforward installation, and wide compatibility with various flange standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Butterfly Valve Category

IVTL Butterfly Valve IVGKL/ IVGK/ IVGK-25

Price 1079 INR / Number

Minimum Order Quantity : 10 Millimeters

Material : Cast Iron

Shape : Wafer Type

Media : Other, Water, Air, Oil, Gas

Pressure : Other, PN10 / PN16

CI030 Cast Iron Butterfly Valve PN-16 SS304 Disc (Wafer Type)

Price 1070 INR / Number

Minimum Order Quantity : 100

Material : Cast Iron

Shape : Round

Media : Water

Pressure : High Pressure PSI

CI029 Cast Iron Butterfly Valve PN-16 (Wafer Type)

Price 1080 INR / Number

Minimum Order Quantity : 100

Material : Cast Iron

Shape : Round

Media : Water

IVDXR Valve

Price 1120 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel

Shape : Straight

Media : Other, Air, Water, Gas, Oil

Pressure : Other, Up to 10 Bar

CELESTE TRADING CORPORATION

GST : 27AADFC6410F1ZV

GST : 27AADFC6410F1ZV

6, Gulmohar Orchids, First Floor, Bibwewadi Kondhwa Rd, Sahaney Sujan Park, Lullanagar,Pune - 411040, Maharashtra, India

Phone :07317168914

|

|

CELESTE TRADING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry